What Equipment is Needed for Cashew Nut Processing Line?

Cashew nuts are known as one of the four dried fruits in the world and are native to the Americas. Cashew nuts are rich in nutritional value and their edible part is the crescent-shaped part that is born on the top of the pseudocarp. Cashew nuts are about 25 mm long. The color of ripe cashews is yellowish-brown. If you find the color white when selecting, then it may be bleached, do not buy. Cashew nuts have a hard shell and are covered with seed kernels. Cashew nuts contain high-calorie content and their calorie source is mainly fat, followed by carbohydrates and protein.

Equipment included in the cashew nut processing line

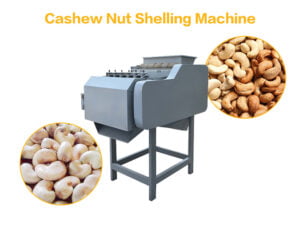

Cashew nuts need to be removed from their shells before consumption and then processed. If you want to remove the shells in large quantities then you need to use the cashew nut processing line. But the removal of shells in large quantities requires the use of cashew nut hulling production lines. Therefore, we will introduce what machines are available in the cashew nut processing line.

Raw cashew grading machine

Cashew boiling machine

Cashew cutting machine

Cashew nut shell kernel separator

Cashew dryer machine

Cashew peeling machine

What are the highlights of the Taizy cashew nut production line?

- Electronic synchronous control system. Our cashew processing line adopts an electronic synchronous control system. By adjusting one control point in a real section, the section can be changed according to the process rhythm.

- Automatic hulling technology. No need to place materials, automatic drop, or positioning. Multi-loop and multi-channel multiple times separation and shelling. The cashew nut shelling machine has high hulling efficiency.

- The peeling process adopted by the cashew nut peeling machine is a combination of flexible beating and loosening, continuous air method peeling and sieving. Therefore, the peeling line features a high peeling rate and a low broken kernel rate.

- The shelling rate of the cashew nut processing line is ≥98%, the whole kernel rate is ≥91%, and the moisture content of the finished product is ≤5%.