Efficient Method to Separate Cashew Shell and Kernels

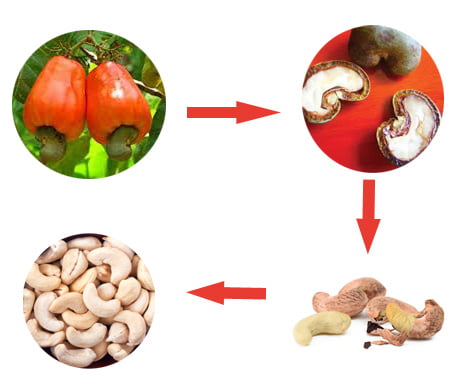

Traditional cashew processing method

Cashew nut, also be known as the “wonder nuts”, has received popularity from people leading a healthy life all around the world, India as the biggest cashew producer, processor, exporter is with an estimated annual production of about 4.60 lakh tonnes of raw cashew nut. It has the potential to provide source of livelihood for the cashew growers, empower rural women in the processing sector, create employment opportunities and generate foreign exchange through exports. However, due to the insufficient development of mechanization of cashew processing line, the cashew shelling, separating process can be tedious consume intensive labor.

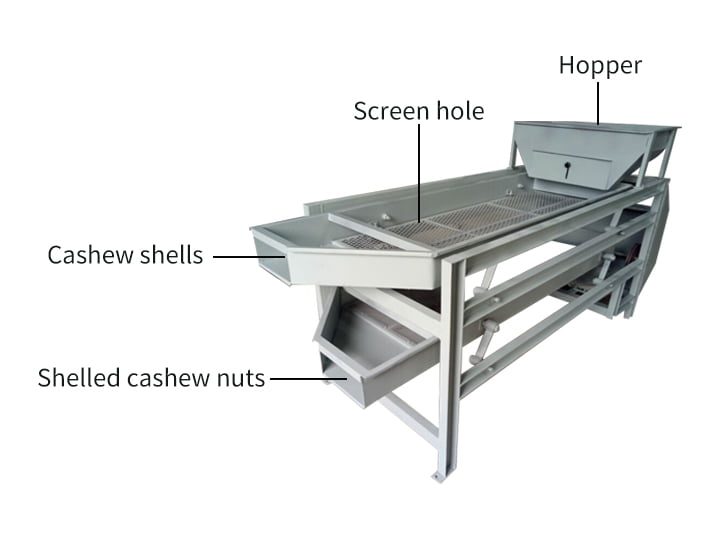

Mechanized cashew processing method

In contrast with the traditional man-powered peeling, shelling and separating method, the production process by advanced cashew processing line doubles or triple the working efficiency by shorten the working time with the cashew output increased in a profound way. The compound utilization of the cashew processing line invented, developed by Shuliy Machinery independently is characterized by its heavy yield, high efficiency, low damage rate, pure and hygiene processing, low maintenance, and sincere after-service. Among the advanced cashew processing line, the double layer cashew kernel and shell separating machine can separate cashew nut and shell through vibration motivated by a powerful rotor, it is of high separating rate in a short time.