Cashew Shelling Machine

A cashew shelling machine is a sheller machine that assists in breaking the shells of cashew nuts. According to the degree of automation, the cashew nut breaking machine has a manual type, semi-automatic type, automatic sheller machine, and large shelling group. As the output of shelling machines increases, the degree of automation and output of cashew shelling machines increase accordingly.

Watch the Video of the cashew shelling machine

Automatic Cashew Cracking and Shelling Machine

The cashew nut shelling unit is specialized in removing cashew nutshell. The full production line is automatic, first separated cashew nuts into 3-5 grades(18 mm.20mm. 22mm. 24mm. 26mm) by man work or machine, Feeding action is completed automatically. Simple operation and high efficiency make it a good choice for processing cashew nuts.

Cashew nut breaking machine working principle

The cashew nut sheller machine continues the principle of manual shelling. After pouring the cashew nuts into the feeding hopper of the peeler, the cashew nuts fall into the small holes with the rotation of the chain. Then, the chain of the machine takes the cashew nuts to the position of the blade to break the shell. The nut shelling machine can equip with a screening machine to increase the braking efficiency.

Cashew nut cracking machine Features:

- Easy to operate, low energy consumption.

- With high capacity and low noise. You can crack 6,8,10, 12, 14 cashew nuts, and so on at the same time.

- Reasonable design, exquisite structure, and small floor space.

- The cashew shelling machine has a high degree of automation, which reduces the intensity of manual labor.

- It has a variety of models to choose from, which can meet the production requirements of manufacturers of different specifications.

- The automatic cashew shelling machine adopts the horizontal placement of materials to increase the shelling efficiency and reduce the breaking rate.

- The cashew contact part of the machine adopts stainless steel, and the rest adopts carbon steel. It reduces production costs while meeting food safety production requirements. We can customize the machine according to customer requirements.

- Shelling after grading by the classifier, the shelling rate, and whole kernel rate of cashew nuts can be improved.

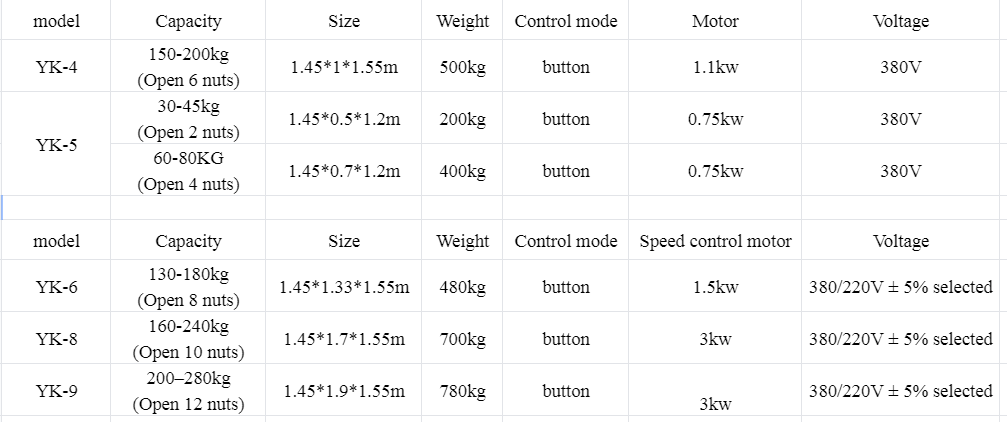

Details parameters:

| Frequency | 50HZ |

| Shell opening rate | 90–95% |

| Unopened rate | 3% |

| Breakage rate | less than 5-10% |

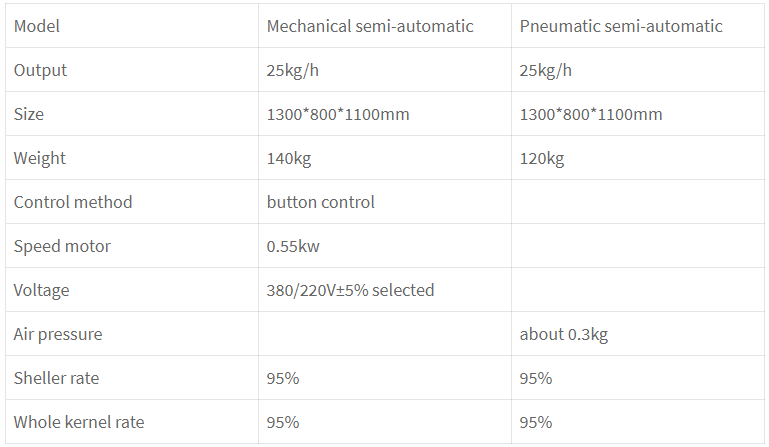

Semi-automatic Cashew Sheller Machine

The semi-automatic cashew shelling machine is divided into pneumatic and mechanical semi-automatic machines.

Machine Introduction

The pneumatic cashew shelling machine uses an air pump to control the mechanical rod to press down the cashew nuts, while the mechanical machine uses a motor to drive the machine.

Both machines require manual material placement. The big difference from the manual peeling machine is that the cashew nut cracking machine can place several cashew nuts at one time, which greatly increases the production efficiency.

Details parameters:

Manual Cashew Nut Shelling Machine

The manual sheller machine is the oldest machine in the development of the sheller. The machine uses a foot-operated operation and manual discharging. When breaking the shell, it is necessary to manually match the cashew nut with the machine blade. Then the footswitch makes the blade rotate to open the shell. The nuts cracking machine requires labor, and the efficiency of the shell opening is low, and the shell opening rate is not satisfactory.

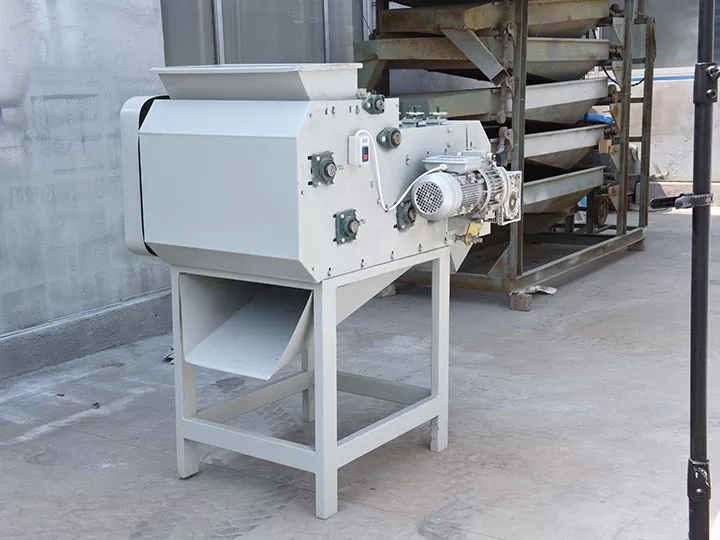

Large Cashew Nut Shell Breaking Machine Group

The fully automatic sheller machine is a combination of single cashew nut sheller machines. According to the requirements of the output, you can match with different numbers of shelling machines. The automatic shelling unit is usually composed of a hoist, a distributor, several automatic cashew nut cracking machines, and a screening machine.

Working principle of nuts shelling machine

First, use the conveyor belt to transport the cashew nuts to the hopper of the dispenser. The hopper’s bottom contacts with several conveying material pipes. Through the pipes, these cashew nuts are divided into different positions of the sheller machine. The dispenser can automatically control the amount of material divided each time. After the cashew nut enters the shelling machine, the separated shells and kernels fall onto the screen machine. Under the action of the vibrating screen, the cashew kernels and shells of different weights are separated.

Cashew nuts cracking machine features

1. Fully-automatic cashew nut breaking machines can realize the entire process from feeding, peeling, and screening, with a high degree of automation.

2. The machine has a stable structure, high peeling efficiency, and a high whole kernel rate.

3. This large cashew shelling machine group is suitable for large cashew nut processing plants and has high production efficiency.

4. It can match with multiple cashew nut sheller machines to achieve different output requirements.