Can a Cashew Kernel Separator Be Used for Other Types of Nuts?

When it comes to nut processing, efficient cashew nut processing machines play a crucial role in streamlining operations. Cashew kernel separators are widely used in the industry to separate cashew kernels from their shells effectively. However, a common question that arises is whether these separators can be utilized for other types of nuts as well. In this article, we will explore the versatility of cashew kernel separators and their applicability beyond cashews, shedding light on the potential benefits and limitations.

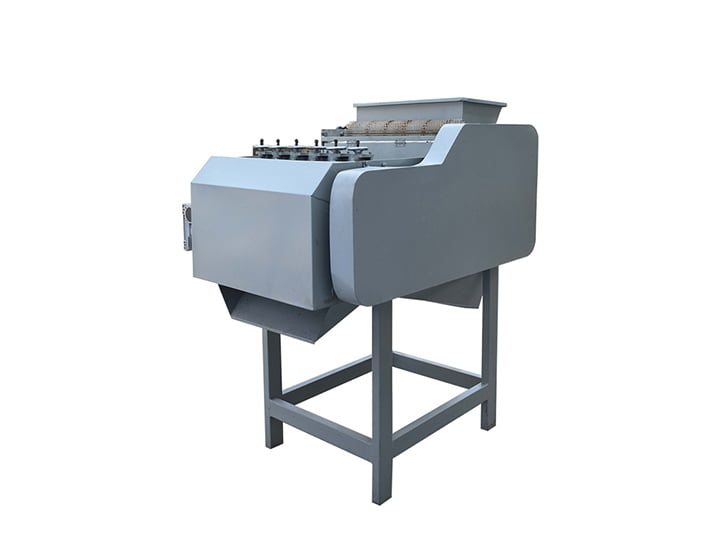

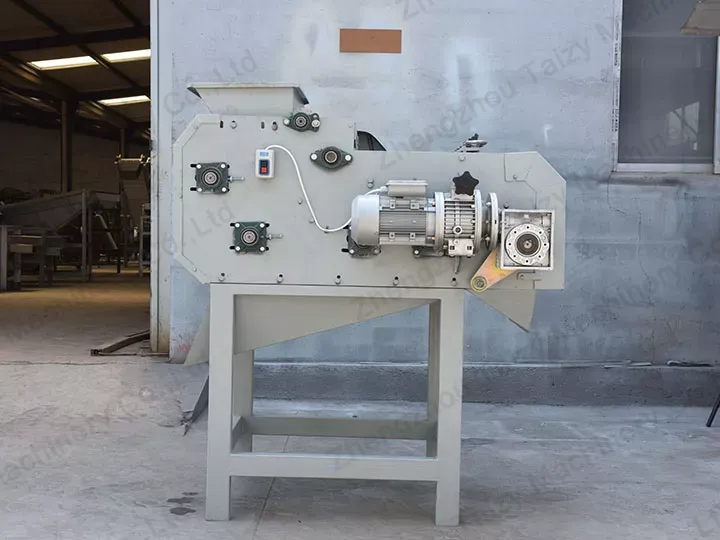

What is Cashew Kernel Separator?

Before delving into the versatility of cashew kernel separators, it is essential to comprehend their working principle. Cashew shell and kernel separator machine employ mechanical and sometimes pneumatic mechanisms to separate cashew kernels from their shells, ensuring high efficiency and minimal damage to the kernels.

Assessing Compatibility with Other Nuts

While cashew kernel separators are specifically designed for cashews, their potential for processing other types of nuts depends on various factors. Let’s examine the key considerations:

- Size and Shape: The size and shape of nuts can significantly impact the effectiveness of a cashew kernel separator. Nuts that closely resemble cashews in size and shape, such as almonds and pistachios, may yield favorable results.

- Shell Hardness: The hardness of the nut’s shell is another crucial factor. Cashew shell and kernel separator machine are optimized to handle the moderate hardness of cashew shells. Harder shells, like those found in macadamia nuts or Brazil nuts, may pose challenges for the separator’s mechanisms.

- Kernel Fragility: The delicacy of the nut’s kernel is an important consideration. Cashew kernel separators are designed to handle the relatively robust cashew kernels. Nuts with more fragile kernels, such as walnuts or pecans, may require modified separator settings to prevent excessive breakage.

Potential Benefits and Limitations

Expanding the use of cashew kernel separators to other nuts can offer several advantages, including increased efficiency, reduced labor costs, and improved product quality. However, it is crucial to acknowledge the limitations:

- Equipment Adjustments: Adapting a cashew kernel separator for other nuts may require adjustments and fine-tuning of the machine’s settings. This process can involve trial and error to optimize separation efficiency.

- Nut-Specific Considerations: Each nut variety has unique characteristics that influence its processing requirements. Some nuts may require pre-treatment steps, such as soaking or roasting, to enhance separation efficiency.

While cashew shell and kernel separator machines are primarily designed for cashews, their application to other nuts is possible with careful consideration of factors like size, shell hardness, and kernel fragility. Adapting the machine and fine-tuning its settings may be necessary to achieve optimal results. By exploring the versatility of cashew kernel separators, nut processing facilities can potentially enhance efficiency and productivity in their operations.