Cashew Shelling from Manual to Machine

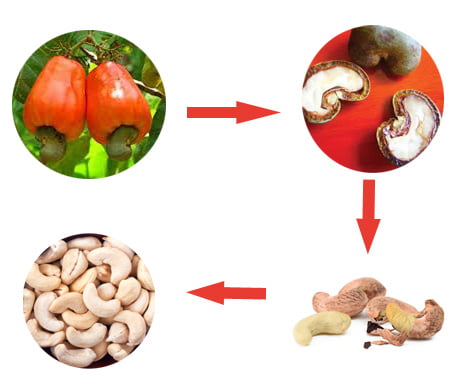

Due to the particularity of cashew nuts, the original manual cashew nuts processing mode is adopted widely at present. The procedures are as follows:

Steam: steam the dried raw cashews until the nuts and shell are separated automatically.

Air dry: steam and air dry raw cashews naturally.

Shelling: manually operate the mechanical shell opener, which is simply composed of two blades. Insert the raw cashew nuts between the blades and start with handling the operating rod. The operating rod drives the blades close together and squeeze cracks the cashew shell. Through this method, 15-20 kg can be produced per person per working day (within 8 hours), and the intact rate of cashew nuts can reach 90%.

Baking: after the nuts and shell are separated, bake or cook the nuts to reduce moisture content and to loosen the seed coat.

Peeling: the seed coat is removed manually. The average yield per person per working day is 9-0 kg.

Selecting: Selection of nuts according to management and supervision act on export quality.

Humidity control: control the humidity environment of nuts before packaging. If nuts are too dry when packed, they are inclined to be broken during transition. If the nuts are too wet, they are liable to be mildewed or oxidized.

High temperature sterilization: cashew nuts are sterilized at high temperature before packaging.

Packaging: cashews have the property of absorbing moisture, so the oxygen and water permeability of the packaging must be avoid. Vacuum packing or carbon dioxide filled packing can be used.

Food processing plant using peelling equipment

Cashew nut shelling machine: cashew nuts are divided into three to five levels according to its width before shelling by cashew rating sorting machine. The yield, breakage rate and intact kernel rate are largely depends on the proficiency of operators.