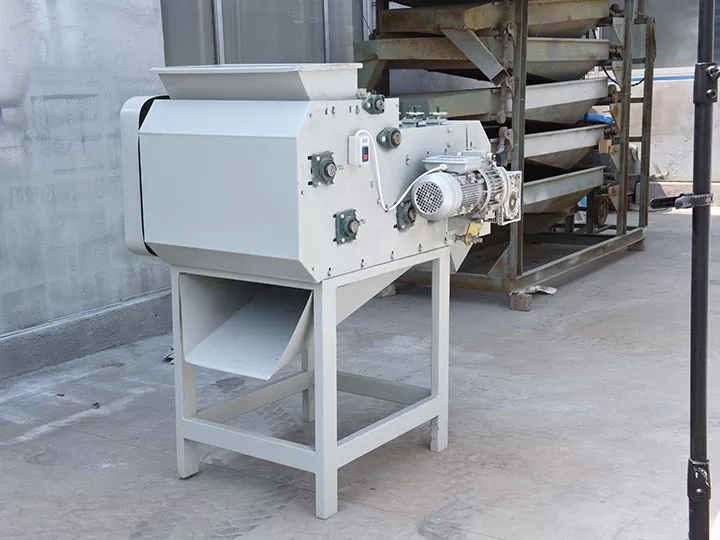

Automatic cashew breaking machine in India

Cashew nut’s outer layer is the shell, and the inner layer is the nuts, with outside a membrane called the skin. Fresh cashew nut shell closely combined with nuts is hard to be separated, and their liquid (also called cashew shell oil) is characterized by its corrosive feature, once contact with human skin it will cause allergic reaction or inflammation, meanwhile, with cashews strange shape, cashew shelling and peeling is of certain difficulty.

Field of technology

The advanced practical machine for cracking and shelling cashew nuts solved problems such as unsatisfactory manual shelling rate, high damage rate, poor kernel integrity rate, poor adaptability, high operating cost, and low safety performance, thus satisfying customers’ requirement on safety production with large-scale cashew shell shelling.

Technical background

At present, the market of cashew breaking machine mostly adopts man-power-aided method: cut cashew by hand, then twirl the cutting direction to realize the shelling effect. Manual shelling is mainly faced with the following problems: 1. High loss rate 2. low safety 3. High cost.

Practical invention

In order to solve defects existing in the traditional manual machine, the mow model provides an advanced cashew breaking machine: the distance between two knife rollers can be adjusted, realizing automatic production, greatly reducing the cost, improving the success rate of decanting, and not cutting to the finger of the processor, with safety guaranteed. Practical application in India shows Shuliy’s cashew breaking machine is of reasonable structure, high degree of continuous, can effectively continuous shelling, high shelling rate, complete separation, and high whole kernel rate, and the shelled nuts is of stable quality, improved flavor, and the added economic value.